Application precautions and custom screen printing

Application precautions

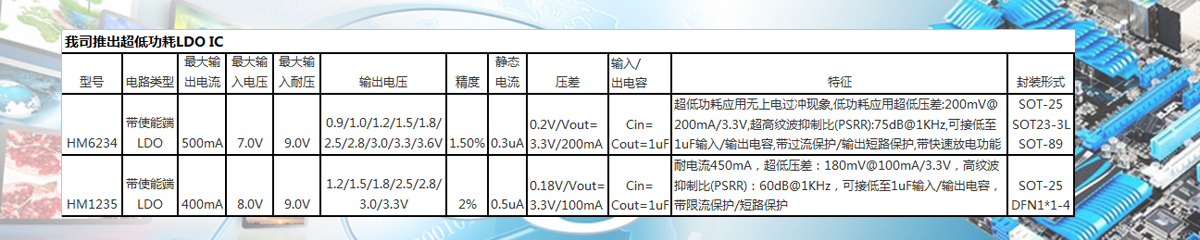

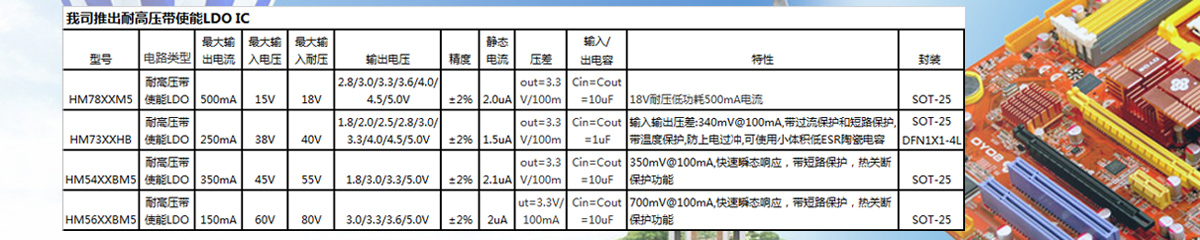

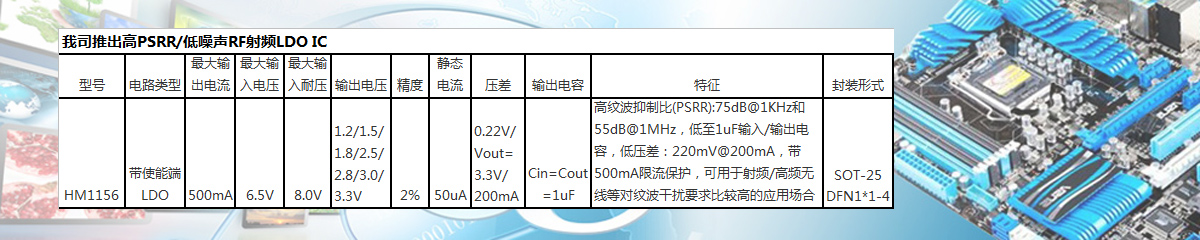

For LDO/DC-DC power supply ics and linear /DC-DC LED driver ics:Input attention to increase the capacitor filter voltage regulation, small capacitance to remove the peak voltage.

Pay attention to increase the capacitive filter voltage regulation.

Input and output capacitors should be as close to the pin of the IC as possible.

If necessary, clamp protection should be connected to the clamp diode at the input end.

For charging ics:

The input end and BAT pin need to increase the capacitor filter voltage regulation, and the small capacitor removes the peak voltage. (If necessary, clamp protection needs to be done at the input /BAT pin clamp diode)

The capacitors of the input end and BAT pin should be as close as possible to the pin of the IC.

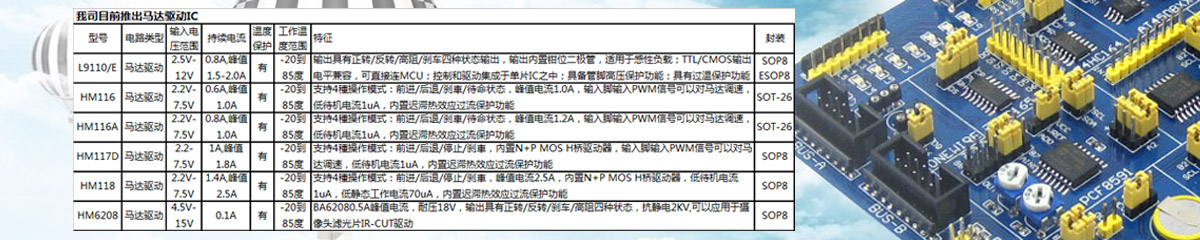

For motor drive ics:

At the input end of the power supply, it is necessary to increase the capacitor 220uF-470uF to filter and stabilize the voltage, and the small capacitor 0.1uF to remove the peak voltage and absorb the instantaneous surge current.

Between the motor/motor load (between the output pins of the IC), a small capacitor 0.1uF is required to remove the peak voltage and absorb the instantaneous surge current.

The above capacitors should be as close as possible to the pin of the IC.

If necessary, clamp protection should be connected to the clamp diode at the input end.

Inductance note to use a winding power inductor with a magnetic core, try to choose an inductor with large current and small internal resistance.

The temperature rise current/saturation current of the inductor should leave a margin that is greater than the maximum current that can be passed. The power of the inductor is also greater than the output power.

ESOP8/DFN2X2-6L/DFN2X2-8L/DFN3X3-8L package, with heat sink at the bottom, pay attention to the heat dissipation of the IC bottom and PCB.

EMC has the following measures for reference, the specific parameters still need to be adjusted:

1. Ensure that the inductance working waveform of the line under load is a standard square wave, and do not have ringing and waveform jitter problems, if necessary to eliminate them.

2. Ensure that the working waveform of the inductor in the load state is a standard square wave, and then add the filtering part:

a. Add 104 capacitors to both input and output capacitors for absorption.

b. Inductance with shielding inductance, reduce external radiation.

c. Inductance network to the ground plus a series of capacitors under the resistance to do high-frequency absorption. (Resistance value of 2 Ohm --10K, capacitance value of 102--104, need to debug the decision: resistance value gradually reduce, capacitance value gradually increase, until EMI has been tested and the margin is enough)

Reflow welding: Maximum temperature is not more than 260 degrees @ maximum time is not more than 30 seconds

Wave soldering: Maximum temperature is not more than 240 degrees @ maximum time is not more than 5 seconds

Custom silk screen printing

Our company can order silk screen printing according to customer requirements, but the order contract should be noted: If the printing content produces third-party intellectual property rights disputes and trademark disputes, the consequences shall be borne by the customer.